Wonderful Info About What Are The 4 Main Components Of A PLC

Understanding Programmable Logic Controllers Messung IAC

Understanding the Brains Behind Automation

1. What Makes a PLC Tick? It's More Than Just Wires!

Ever wondered how those super-efficient machines on factory floors run so smoothly? A Programmable Logic Controller (PLC) is often the unsung hero behind the scenes. Think of it as the industrial world's super-smart, reliable computer. It's not playing video games, but it's orchestrating some pretty complex processes. We're going to break down what makes these controllers tick, focusing on the four main components that keep them humming.

Imagine a conductor leading an orchestra. The PLC is the conductor, and each instrument (or machine) needs precise instructions to play its part correctly. Without the conductor, you have chaos. Without a PLC, you have production nightmares! Understanding these components will give you a glimpse into the world of industrial automation, even if you're just curious about how things work.

So, why is this important? Well, whether you're an engineer, a technician, or just someone interested in technology, knowing the basics of PLC operation is incredibly valuable. It opens up a whole new world of understanding about how modern manufacturing, and many other industries, function. Plus, it's just plain cool!

Let's demystify this technology. We will dissect the PLC into its fundamental parts, it's not as scary as it looks at first glance. By exploring each component, you'll not only gain knowledge, but also appreciate the ingenuity behind these powerful control systems.

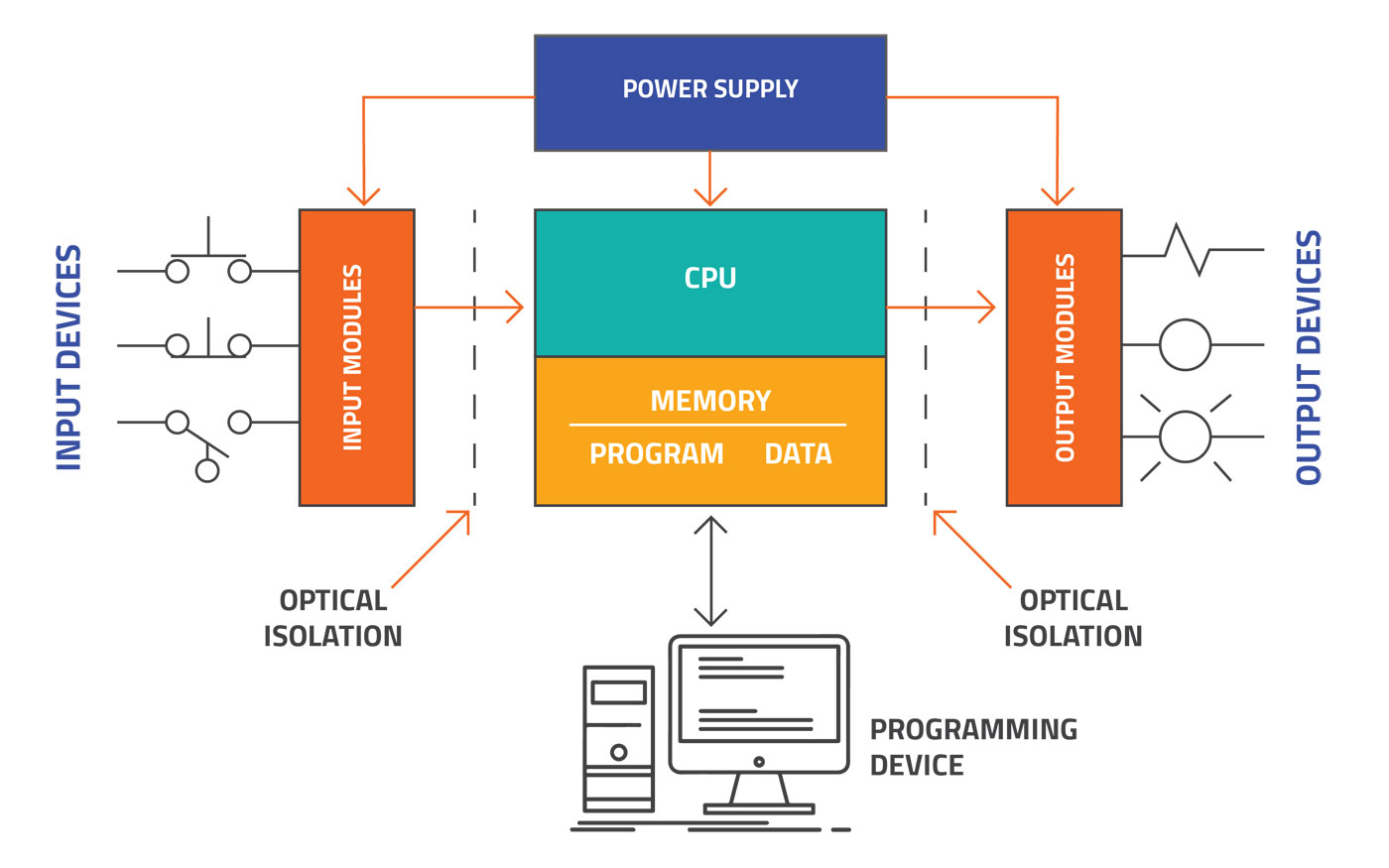

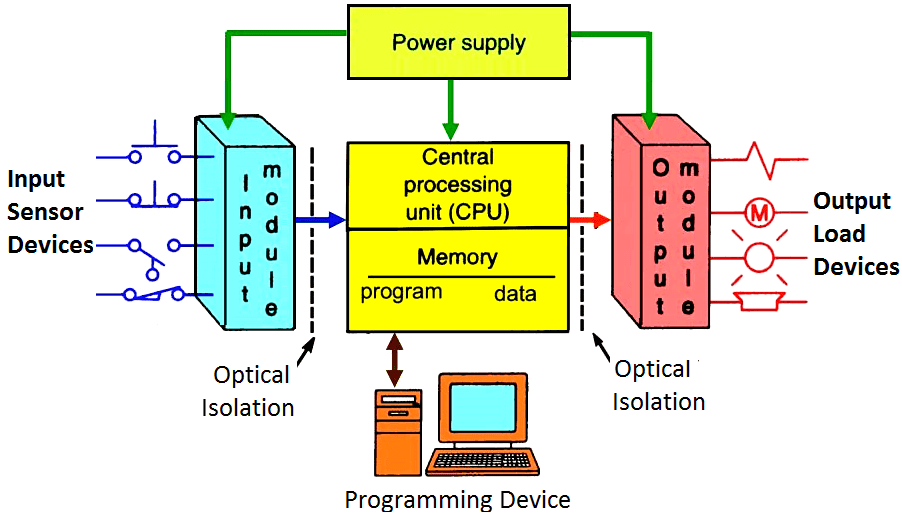

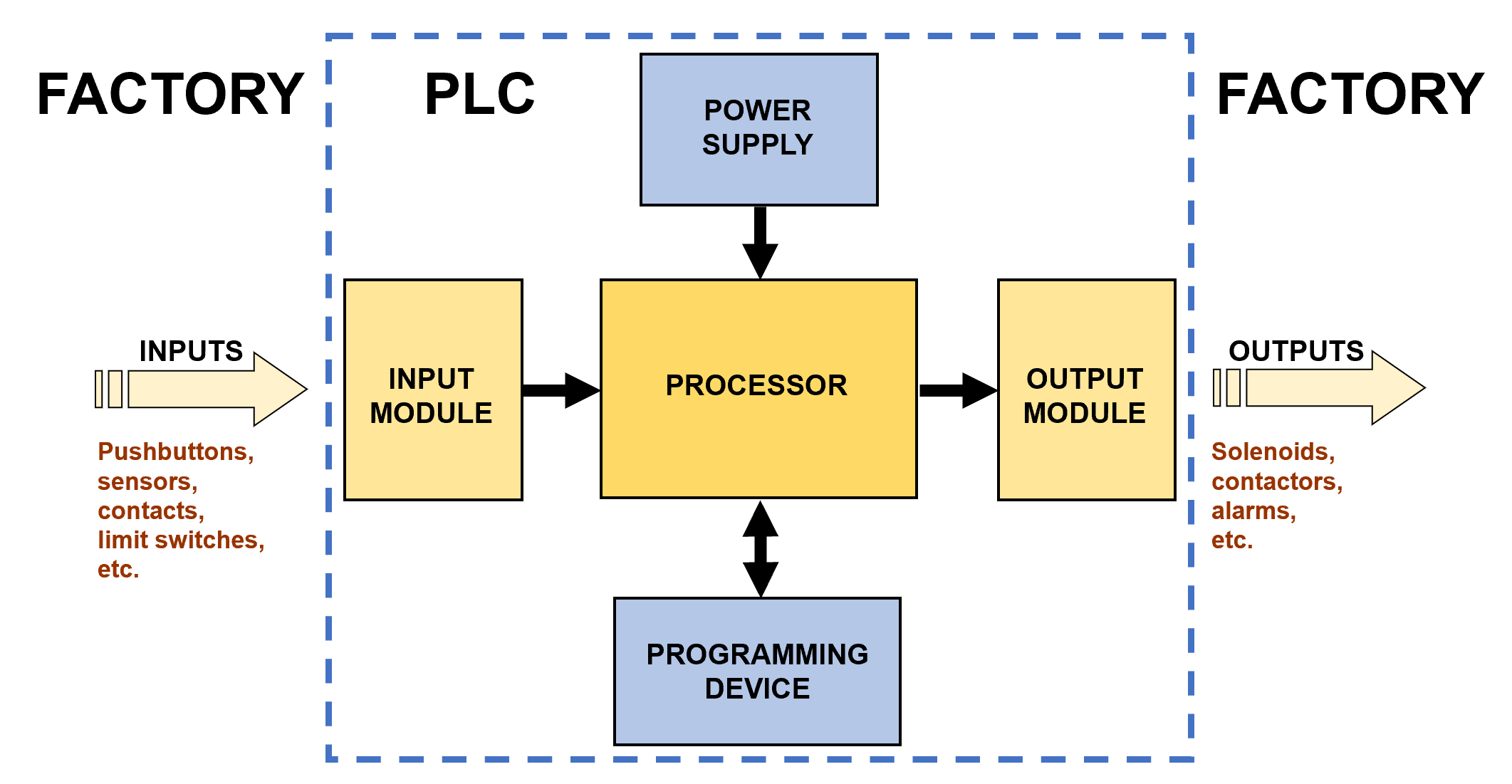

Components Of PLC

The Powerhouse

2. The PLC's Brain

At the heart of every PLC lies the CPU, or Central Processing Unit. This is essentially the brains of the operation. Just like your computer's processor, the CPU is responsible for executing the program you've written and making all the important decisions. It reads the inputs, processes the data according to your instructions, and then sends commands to the outputs.

Think of the CPU as a really, really fast calculator — a calculator that can handle complex logic, timing, counting, and arithmetic operations. It's constantly scanning the input modules, executing the program, and updating the output modules. This cycle happens incredibly quickly, often in milliseconds, ensuring real-time control of your industrial processes. This speed is critical for maintaining accuracy and preventing costly errors.

The CPU also contains memory. This memory stores the PLC's operating system, the user program (your instructions!), and data used during operation. It's like a short-term and long-term memory all rolled into one. Without this memory, the PLC would be unable to retain your program or remember the current state of the system. Therefore, CPU plays critical role to the entire PLC.

Now, let's get real. Sometimes, the CPU can get bogged down if your program is too complex or if there are too many inputs and outputs to process. This is why choosing the right CPU for your application is so important. You want a CPU that's powerful enough to handle the workload without slowing down or crashing. It's like choosing the right engine for your car — you need enough horsepower to get the job done.

Sense and Respond

3. Connecting the PLC to the Real World

Next up, we have the Input and Output (I/O) modules. These modules act as the PLC's senses and muscles, allowing it to interact with the outside world. Input modules receive signals from sensors, switches, and other devices, converting them into a format that the CPU can understand. Output modules, on the other hand, take signals from the CPU and use them to control actuators, motors, valves, and other equipment.

Imagine a bottling plant. Input modules might receive signals from sensors that detect the level of liquid in a tank or the presence of a bottle on a conveyor belt. Output modules would then use these signals to control pumps, valves, and motors that fill the bottles, move them along the conveyor, and cap them. Without these I/O modules, the PLC would be completely isolated, unable to receive information or exert control.

There are many different types of I/O modules available, each designed for specific types of signals. Digital input modules detect on/off signals, while analog input modules measure continuous values like temperature or pressure. Digital output modules control on/off devices, while analog output modules control devices that require a variable signal. Choosing the right I/O modules is essential for ensuring compatibility and accuracy.

Consider this. A faulty input module could cause the PLC to misinterpret a signal, leading to incorrect actions. Similarly, a malfunctioning output module could prevent the PLC from controlling a device, causing production to stop. Regular maintenance and testing of I/O modules are therefore crucial for ensuring reliable operation. Think of them as the PLC's sensory organs and limbs — you need to keep them in good shape!

The Communicator

4. Keeping the Lights On — Reliably

We're powering through this nicely! Now, let's talk about the Power Supply. This component is often overlooked, but it's absolutely critical for the PLC's operation. The power supply provides the necessary voltage and current to all the other components, ensuring that they function correctly. Without a stable and reliable power supply, the PLC could malfunction or even fail completely.

Think of the power supply as the PLC's lifeblood. Just like your body needs a constant supply of oxygen and nutrients, the PLC needs a constant supply of power. Fluctuations in voltage or current can cause erratic behavior, data loss, or even permanent damage. Therefore, choosing a high-quality power supply is essential for protecting your investment.

Power supplies come in various sizes and configurations, depending on the specific requirements of the PLC. Some power supplies are designed to operate on AC voltage, while others operate on DC voltage. Some power supplies also include features like surge protection and over-voltage protection, which can help to protect the PLC from damage caused by electrical disturbances. These protections are like insurance for your PLC, guarding against unexpected power surges.

It's important to ensure that the power supply is properly sized for the PLC and all its connected modules. An undersized power supply could be overloaded, leading to overheating and failure. An oversized power supply, on the other hand, could be unnecessarily expensive. Calculating the total power requirements of your PLC system is therefore a crucial step in the design process. A reliable power supply is the silent partner that enables the entire automation system.

The Interface

5. Giving the PLC Instructions

Last but not least, we have the Programming Device. This is the tool that allows you to create, modify, and upload programs to the PLC. It could be a dedicated programming terminal, a laptop computer running specialized software, or even a handheld programmer. The programming device provides the interface you use to communicate with the PLC and tell it what to do.

Think of the programming device as your translator. You write your program in a programming language that you understand (like ladder logic, function block diagram, or structured text), and the programming device translates it into a format that the PLC can understand. This translation process is called compiling, and it's essential for ensuring that your program runs correctly. It's like giving the PLC a very detailed set of instructions in its own language.

The programming device also allows you to monitor the PLC's operation, diagnose problems, and make changes to the program while it's running. This is invaluable for troubleshooting issues and optimizing performance. You can see the current state of the inputs and outputs, track the values of variables, and even step through the program line by line. It's like having a window into the PLC's mind.

Different programming devices offer different features and capabilities. Some are more user-friendly than others, and some are better suited for specific types of programming languages. Choosing the right programming device can significantly improve your efficiency and reduce the risk of errors. The right programming device transforms you from a mere operator into a PLC whisperer.