Fantastic Info About Are PCBs Still Used In Capacitors

PCBs and Capacitors

1. What's the PCB Story?

Let's dive right in, shall we? You're probably here because you're wondering if those pesky PCBs (Polychlorinated Biphenyls) are still lurking inside capacitors. The short answer is, thankfully, generally no. But like a plot twist in a thriller, there's more to the story. PCBs were once the darling of the electronics industry, praised for their insulating properties, fire resistance, and overall stability. They were used everywhere — in transformers, hydraulic fluids, and, yes, capacitors. They seemed perfect … until we discovered they were a serious environmental and health hazard.

The problem with PCBs is that they are incredibly persistent in the environment. They don't break down easily and can accumulate in soil, water, and even living organisms. This bioaccumulation leads to health problems in animals and humans, including cancer, immune system issues, and developmental problems. Not a pretty picture, right?

Because of these dangers, many countries, including the United States, banned the production and use of PCBs in the late 1970s and early 1980s. That's the good news! However, the capacitors containing PCBs that were manufactured before the ban are still potentially out there, aging quietly (or not so quietly) in old equipment.

So, while new capacitors aren't being made with PCBs, the legacy of these chemicals continues to linger, requiring careful management and disposal of older electrical equipment. It's like finding an old box of your parents' clothes — a bit of nostalgia mixed with a healthy dose of "what were they thinking?"

Are PCBs Still Used in Capacitors? The Straight Answer

2. Checking Modern Manufacturing

Okay, let's cut to the chase. Are PCBs still used in the capacitors being made today? The reassuring answer is a resounding no. Thanks to international regulations and heightened awareness, manufacturers have moved away from using PCBs in new capacitors. Instead, they're using safer alternatives that don't pose the same risks to human health and the environment. It's kind of like swapping out lead paint for something, well, not poisonous!

Modern capacitor manufacturing focuses on using environmentally friendly materials and processes. These newer dielectrics offer similar performance characteristics to PCBs without the associated health hazards. The industry has adapted, innovated, and generally done a pretty good job of leaving PCBs in the past. Think of it as the electronics industry going green — a welcome change!

But it's always a "buyer beware" situation, right? Ensure youre purchasing capacitors from reputable sources that adhere to current environmental standards. Look for certifications and compliance statements that guarantee the absence of PCBs and other harmful substances. Due diligence can save you from a lot of potential headaches down the road.

Ultimately, the modern capacitor landscape is a far cry from the PCB-laden days of the past. Manufacturers are committed to sustainability, innovation, and the well-being of both consumers and the planet. Its a win-win situation, even if it took us a while to get there.

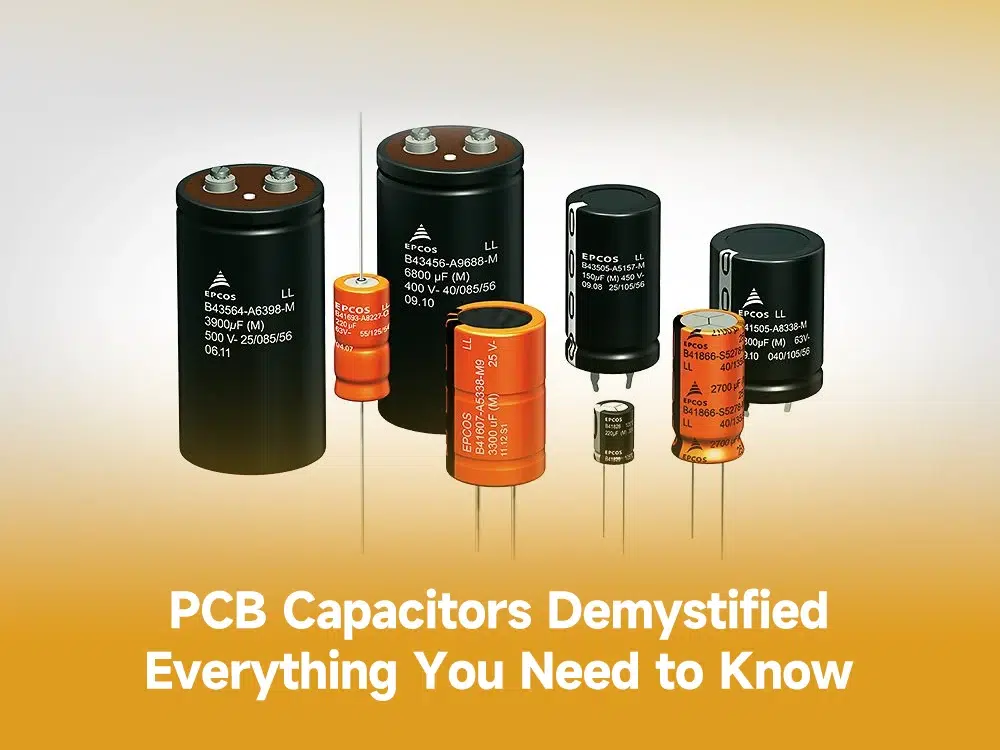

PCB Capacitors Demystified Everything You Need To Know IBE Electronics

What About Older Equipment? A Word of Caution

3. Oldies But Not Goodies

Now, let's shift our focus to the elephant in the room: older equipment. If you're dealing with electrical equipment manufactured before the PCB bans, there's a chance it could contain capacitors with PCBs. Think old radios, vintage appliances, or industrial machinery from the 70s and 80s. These aren't just relics; they could be potential sources of PCB exposure if not handled carefully. It's like discovering a hidden treasure — except the treasure is actually a potential health hazard!

Identifying equipment that may contain PCB capacitors can be tricky. There's no easy way to tell just by looking at it. Typically, you'd need to check the equipment's nameplate or documentation for information about the capacitor type and manufacturer. If you're unsure, it's always best to err on the side of caution and assume the presence of PCBs.

Handling equipment that potentially contains PCBs requires care. If the capacitors are intact and not leaking, the risk of exposure is relatively low. However, damaged or leaking capacitors can release PCBs into the surrounding environment. Always wear gloves and protective clothing when handling such equipment, and avoid direct contact with any potentially contaminated materials.

Proper disposal is absolutely crucial. Don't just toss old equipment with PCB capacitors into the trash. Contact your local environmental agency or hazardous waste disposal facility for guidance on how to safely dispose of these items. They have the expertise and resources to handle PCBs responsibly and prevent further environmental contamination. It's all about being a good steward of the planet, one old capacitor at a time.

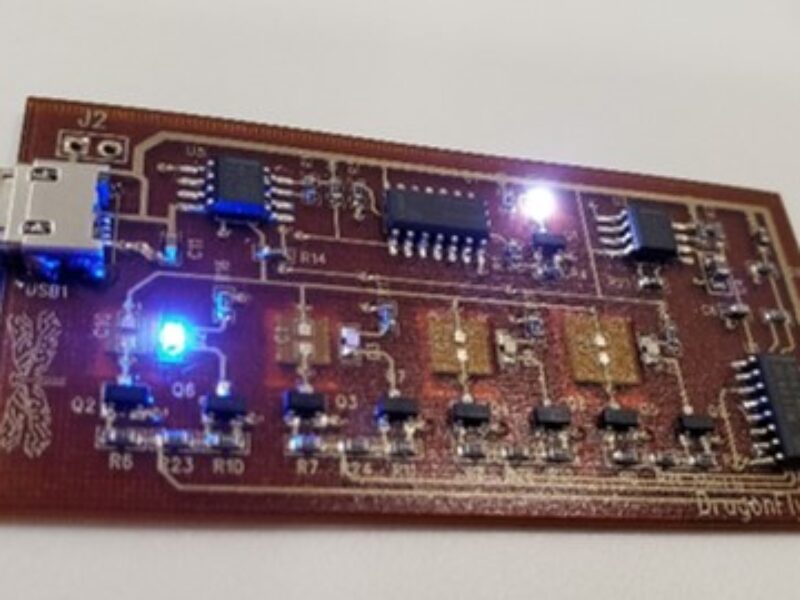

Journey Into PCB Transformer Roles, Parts, And Spotting IBE Electronics

Identifying and Managing PCB Capacitors

4. Detective Work for DIYers (and Professionals!)

So, how do you actually go about figuring out if a capacitor contains PCBs and, more importantly, what do you do about it? Identifying these potential hazards requires a bit of detective work. First, check the equipment's documentation. Look for any mention of PCBs, Aroclor (a common PCB trade name), or specific capacitor types known to contain PCBs. Manufacturer's datasheets or service manuals can be goldmines of information.

If documentation is scarce or nonexistent (as is often the case with older equipment), you might need to rely on visual inspection. Look for markings on the capacitor itself, such as the manufacturer's name, model number, or any symbols indicating the presence of PCBs. Be aware that some capacitors may not be clearly labeled, so a lack of markings doesn't necessarily mean it's PCB-free.

Once you've identified a capacitor that might contain PCBs, the next step is to assess its condition. Is it intact and sealed, or is it leaking or damaged? Leaking capacitors pose a greater risk of exposure and require immediate attention. Don't attempt to repair or dismantle the capacitor yourself. Instead, contact a qualified environmental professional for assistance.

Managing PCB capacitors involves proper handling, storage, and disposal. Store potentially contaminated equipment in a secure area, away from direct sunlight and extreme temperatures. Avoid activities that could damage the capacitors, such as dropping or crushing them. When it comes time to dispose of the equipment, follow all applicable regulations and guidelines. Use a certified hazardous waste disposal facility that can safely handle PCBs. Remember, it's not worth risking your health or the environment to save a few bucks.

The Future of Capacitor Technology

5. Innovation and Alternatives

Let's look ahead, shall we? The good news is that the capacitor industry is constantly evolving, with a strong focus on developing safer and more sustainable alternatives to PCBs. Researchers and engineers are exploring new materials and designs that offer improved performance without the environmental baggage. Its like the tech worlds version of a superhero origin story — fighting for a cleaner, greener future!

One promising area of research is the development of bio-based dielectrics. These materials are derived from renewable resources, such as plant oils and cellulose, making them biodegradable and environmentally friendly. They offer comparable electrical properties to traditional dielectrics, but without the harmful effects of PCBs. It's like swapping out plastic for bamboo — a much more sustainable choice.

Another trend is the miniaturization of capacitors. By using advanced manufacturing techniques, engineers are creating smaller and more efficient capacitors that require less material. This reduces the overall environmental impact of capacitor production and disposal. It's like packing more punch into a smaller package — a win for both performance and sustainability.

The future of capacitor technology is bright. With ongoing innovation and a commitment to environmental responsibility, we can look forward to a world where capacitors are not only essential components of electronic devices but also contribute to a healthier and more sustainable planet. Its a vision worth striving for, one capacitor at a time. The move towards PCB-free capacitors represents a significant step forward in environmental protection and public health, proving that technology can be both powerful and responsible.