Real Info About Can PWM Be Negative

Decoding PWM

1. Understanding the Basics of Pulse Width Modulation

Pulse Width Modulation (PWM) is a technique used to control the amount of power delivered to a device by varying the width of a pulse. Think of it like a light switch that flicks on and off really, really fast. The longer the switch stays "on" during each cycle, the more power gets through. It's incredibly useful in everything from controlling motor speed to dimming LED lights. Now, the big question: can PWM really be negative? The simple answer is no, not in the way we typically think about it.

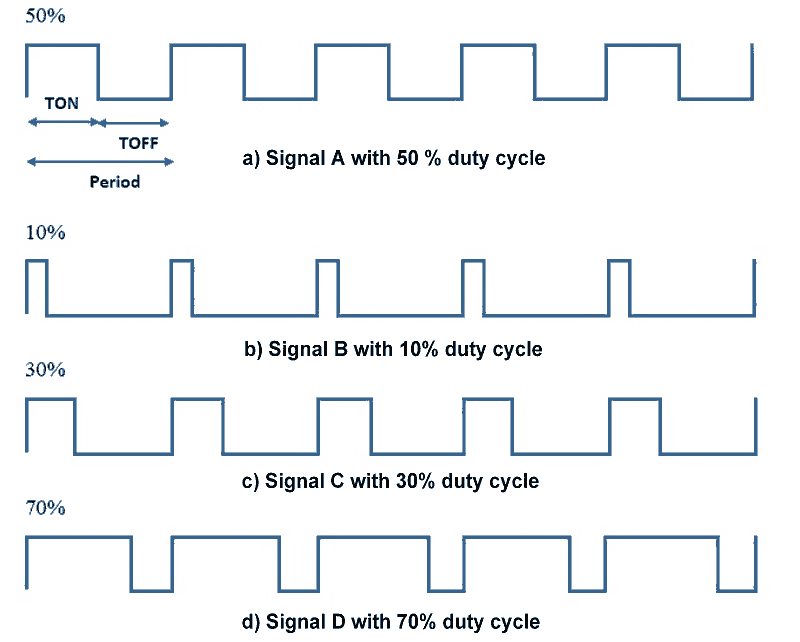

Lets dive a bit deeper. PWM is all about the duty cycle. The duty cycle represents the percentage of time the signal is high (on) versus the total cycle time. So, a 50% duty cycle means the signal is on for half the cycle and off for the other half. A 100% duty cycle means the signal is always on, effectively providing full power. A 0% duty cycle, conversely, means the signal is always off, providing no power. You can already see the boundary here.

Negative? Well, duty cycles are expressed as percentages, ranging from 0% to 100%. Its like saying, "I'm going to give you -20% of the cake." It just doesn't compute! So, in the standard PWM implementation, you wont find any negative values. Its a fundamental limit of how the technique operates. But hold on; there's a twist!

Imagine you're trying to control the direction of a motor. One common approach is to use two PWM signals. One controls the forward direction and the other the reverse. You might not think of it as negative PWM, but effectively, one signal is "canceling out" the effect of the other. If the forward PWM is at 75% and the reverse is at 25%, the motor will spin forward, but less strongly than if the forward PWM were at 100%. The relative 'strength' can then be considered as how one PWM is more dominant than the other. It's like a tug of war with electricity!

PWM In ARM LPC2148 ARM7LPC2148

The Misconception of "Negative" PWM

2. What People Really Mean When They Say It

Okay, so we've established that standard PWM, as a duty cycle percentage, cannot be negative. But sometimes you might hear someone mention "negative" PWM in a different context. This usually stems from a misunderstanding of what PWM is actually doing or how it's being applied in a particular system. Its less about a negative value and more about relative control.

Often, the term "negative" PWM is used informally to describe the effect of a PWM signal rather than the signal itself. For example, consider controlling the brightness of an LED. You might have a system where a higher PWM duty cycle corresponds to a dimmer LED. In this case, increasing the PWM might feel like a "negative" effect because it's reducing the perceived output. It's all about perspective, isn't it?

Another scenario involves control systems where PWM is used to regulate a parameter around a setpoint. Let's say you're maintaining a specific temperature. A PWM signal might control a heating element. If the temperature is above the setpoint, the PWM duty cycle might be reduced, which could be interpreted as a "negative" adjustment because it's decreasing the heat output. However, the PWM value itself is still positive.

So, while the PWM duty cycle always remains between 0% and 100%, the perceived effect can sometimes be described in negative terms, depending on the application. It is key to remember we are talking about the effect or result of the PWM, not the PWM value itself.

PWM Voltage Converter Connected To The Ac Mains. Download Scientific

Applications Where "Negative PWM" Might Seem Relevant

3. Examples in Motor Control, Audio, and More

Even though PWM itself isn't negative, certain applications can make it feel that way. Motor control is a prime example. Think about driving a robot. You need to control not just the speed of the motors but also their direction. One common method is to use an H-bridge circuit, which effectively allows you to reverse the polarity of the voltage applied to the motor. This reversal of polarity, combined with PWM, creates the illusion of "negative" control.

In audio applications, PWM can be used in Class D amplifiers. These amplifiers use PWM to switch the output transistors on and off rapidly, creating a signal that approximates the desired audio waveform. While the PWM signal itself is still positive, the resulting audio waveform can certainly have negative portions, as it oscillates around zero. This is because the PWM is being used to reproduce a signal that inherently has both positive and negative components.

Another intriguing application lies in active noise cancellation. Here, the goal is to generate a sound wave that is precisely out of phase with the ambient noise, effectively cancelling it out. The system uses microphones to detect the noise, and then PWM-controlled speakers generate the anti-noise signal. The anti-noise signal will have portions that effectively negate the original sound waves. Again, the 'negative' aspect comes from the effect rather than the PWM signal itself.

Even in lighting, you might use PWM to create interesting effects. If you are controlling multiple colored LEDs, a higher PWM value on a blue LED and a very low PWM on a red LED can provide the "negative" effect of reducing red and emphasizing blue, relative to a default value. The possibilities are endless and all boil down to clever manipulation of the output based on positive PWM values.

Beyond the Basics

4. Exploring Bipolar PWM and Other Implementations

While standard PWM uses a unipolar signal (switching between 0V and a positive voltage), there are more advanced techniques that introduce the concept of bipolar PWM. Bipolar PWM involves switching between a positive voltage, 0V, and a negative voltage. This type of PWM is often used in applications requiring bidirectional control, such as motor drives. It allows for a more direct and efficient way to control both the speed and direction of a motor.

One popular implementation is sign-magnitude PWM. Here, the sign of the signal determines the direction, and the magnitude (represented by the PWM duty cycle) determines the speed. For example, a positive sign with a 50% duty cycle might command the motor to rotate forward at half speed, while a negative sign with a 50% duty cycle would command it to rotate backward at half speed. This is about as close as we get to "negative" PWM in a practical sense, although its technically the sign that provides the direction information.

Another approach is space vector modulation (SVM). This technique is often used in three-phase motor drives to generate sinusoidal voltages. SVM uses a combination of PWM signals to create a rotating voltage vector that controls the motor. While the individual PWM signals are still positive, the resulting voltage vector can have both positive and negative components, providing precise control over the motor's torque and speed.

These advanced techniques highlight the flexibility of PWM and how it can be adapted to meet the demands of various applications. While "negative" PWM, in its purest form, doesn't exist, the concept of bipolar PWM and other variations allows engineers to achieve similar results through clever signal manipulation. It pushes the limits of what the basic technique can achieve.

Voltage Mode Pulse Width Modulation (PWM) Controllers Electricity

Frequently Asked Questions (FAQs) About PWM

5. Addressing Common Concerns and Clarifications

Here are some frequently asked questions that I often get about PWM. Understanding these points can help clarify any remaining confusion and ensure you have a solid grasp of the topic.

Q: Can a PWM signal have a negative voltage?

A: Not in the traditional sense. Standard PWM switches between 0V and a positive voltage. However, in advanced techniques like bipolar PWM, you might switch between a positive, 0V, and a negative voltage. But the duty cycle, which is the core of PWM, always stays positive (between 0% and 100%).

Q: Is "negative PWM" just a figure of speech?

A: Mostly, yes. When someone mentions "negative PWM," they're usually referring to the effect of a PWM signal rather than the signal itself. It often indicates an inverse relationship or a controlling action that diminishes a parameter, or an indication of direction.

Q: Where can I learn more about advanced PWM techniques?

A: There are tons of resources available online! Search for "bipolar PWM," "sign-magnitude PWM," or "space vector modulation." Look for articles, tutorials, and application notes from reputable electronics manufacturers. You can also find detailed explanations in textbooks on motor control and power electronics. And don't forget to check out online forums where engineers and hobbyists share their knowledge and experiences.