Unique Tips About What Is The Creepage For 48V

Understanding Creepage

1. What Exactly Is Creepage, Anyway?

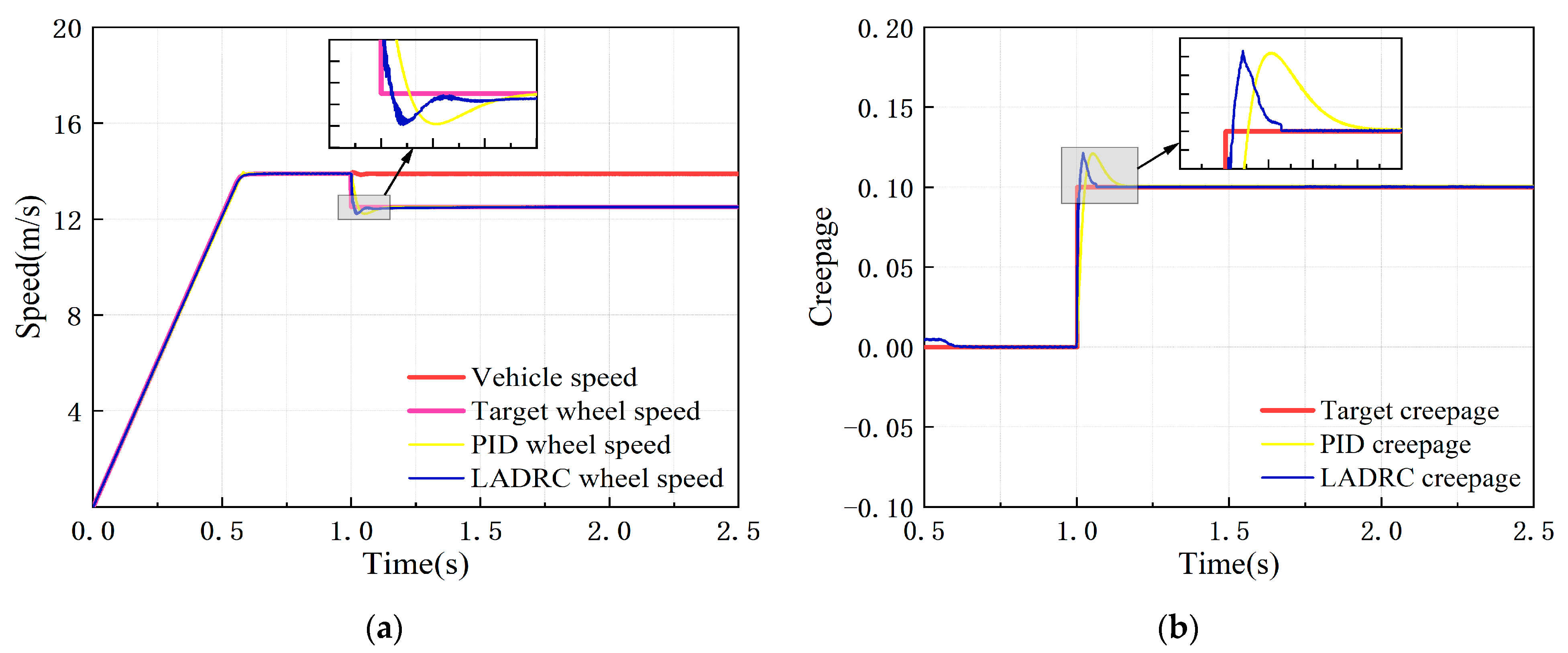

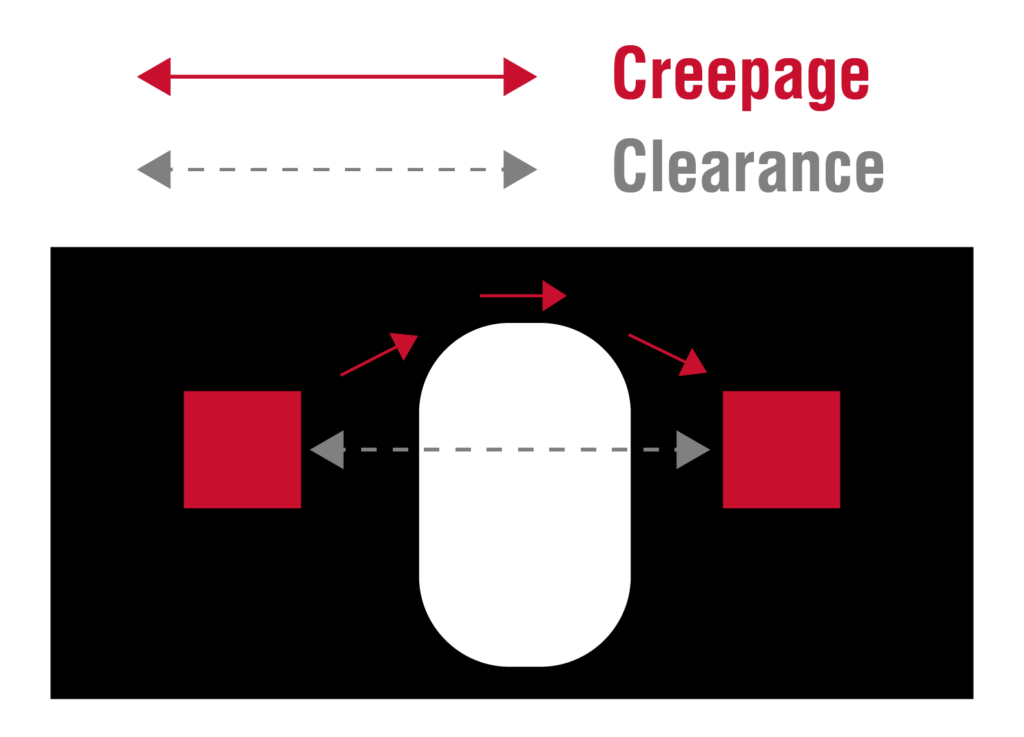

Ever wonder why electronics aren't constantly short-circuiting? A big part of that is creepage! It's not as creepy as it sounds, promise. In the electrical engineering world, creepage refers to the shortest distance along the surface of an insulating material between two conductive parts. Think of it like a sneaky path electricity might try to take, besides the intended route. Its a critical concept, especially when dealing with things like printed circuit boards (PCBs) and other electronic components.

Why is it important? Well, if creepage distance is insufficient, you might experience arcing or even a complete breakdown of the insulation, leading to a short circuit. Nobody wants that! It's basically ensuring electricity stays where it's supposed to, and doesn't decide to go on an unapproved sightseeing tour across your components.

Think of it like this: imagine a stream flowing down a hill. The main riverbed is the intended path (like your wire). Creepage distance is like making sure there are no little side channels that the water (electricity) can sneak off into, potentially causing erosion (damage) elsewhere. We want the water to stay in the river!

So, how does this relate to 48V systems? Good question! While 48V might seem relatively low voltage compared to mains power, it's still enough to cause problems if creepage distances aren't properly considered. Higher voltages generally require larger creepage distances. Proper creepage ensures the safe and reliable operation of any device, so you can keep your stuff running smoothly.

Creepage and 48V

2. Why 48V Demands Attention to Creepage

You might be thinking, "Hey, 48V isn't that much, right?" Well, while it's lower than household voltage (typically 120V or 240V), 48V systems are becoming increasingly common in applications like data centers, telecom equipment, and even electric bikes. The more ubiquitous something becomes, the more important it is to get the safety aspects right.

The key is that even at 48V, under the right (or rather, wrong) conditions, you can still experience dielectric breakdown. This happens when the insulating material between conductors can no longer resist the voltage and suddenly becomes conductive. Humidity, contamination, and altitude can all play a role in affecting the breakdown voltage.

Imagine a tiny speck of dust bridging a gap between two conductors. Add a bit of moisture from the air, and suddenly that speck becomes a conductive pathway! Suddenly, you've got current where it shouldn't be. Ensuring adequate creepage distance helps prevent these kinds of scenarios. It's like having a buffer zone against unexpected problems.

So, specifically for 48V, you need to make sure the creepage distance meets the relevant safety standards. These standards are in place to protect both equipment and people. Ignorance is not bliss when it comes to electricity, and a little planning can save a lot of headache (and potentially worse) later on.

Pcb Design Does Silkscreen Help With Voltage Creepage Distance

Factors Affecting Creepage Distance for 48V

3. Contamination, Altitude, and More!

Calculating the right creepage distance for your 48V application isn't just a matter of pulling a number out of thin air. Several factors come into play, making it a somewhat nuanced calculation. Think of it like baking a cake — you need the right ingredients in the right proportions for the best results.

One big factor is the environment. Are you working in a clean, dry environment? Or is it dusty, humid, or even corrosive? Contamination from dust, moisture, and other pollutants can significantly reduce the effective creepage distance. High humidity can lower surface resistance of insulators, thereby increasing the leakage currents. So clean environment and maintenance is critical.

Altitude also matters. At higher altitudes, the air is thinner, meaning it takes less voltage to cause a spark or arc. This is because there are fewer air molecules to impede the flow of electrons. So, systems operating at high altitudes will need to have larger creepage distances than those at sea level. If you are on Mount Everest with a 48V system, that's a design challenge!

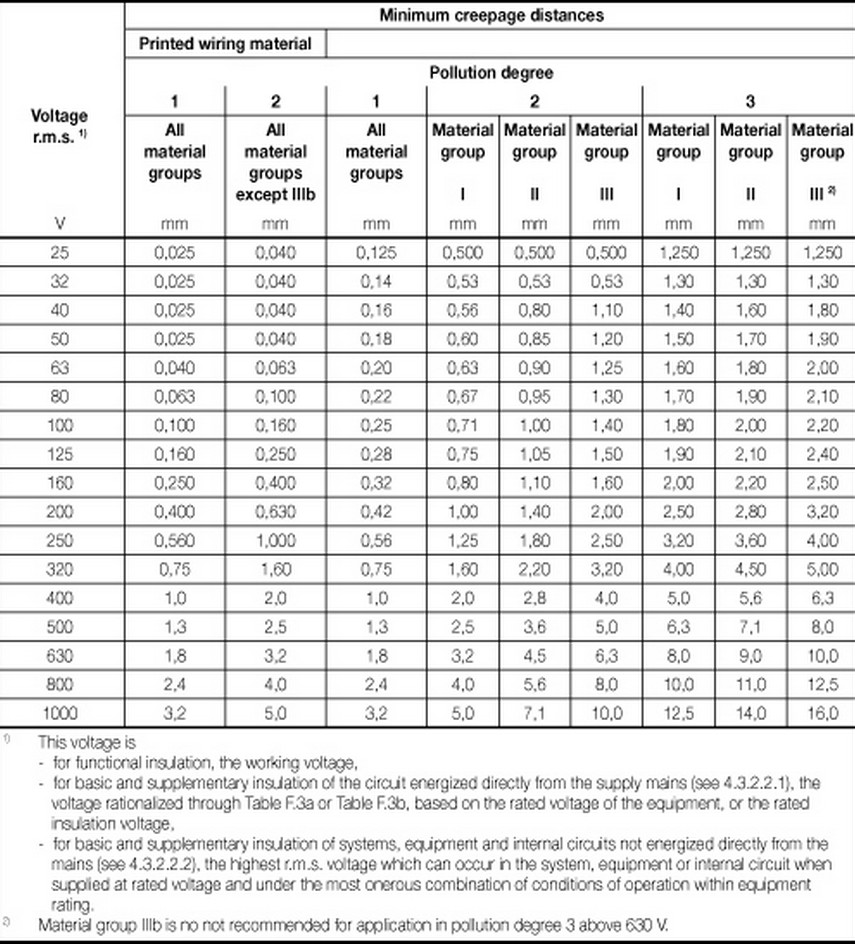

Another crucial aspect is the material group of the insulating material itself. Different materials have different tracking indices, which indicate their resistance to surface tracking (the formation of conductive pathways on the surface). Materials with a lower tracking index will require larger creepage distances. So do your research, or you may end up with a very shocking surprise.

Creepage Distance For PCBs Handling Line Voltage AC? Electrical

Safety Standards and Creepage for 48V Systems

4. Navigating the Regulatory Maze

Alright, let's talk about rules and regulations. (I know, riveting stuff!). The world of electrical safety standards can seem like a tangled web, but understanding them is essential for ensuring your 48V system is safe and compliant. Various international and national standards govern creepage distances, and the specific standard you need to follow will depend on the application and the region.

For example, standards like IEC 60950-1 (now largely superseded by IEC 62368-1) and UL 60950-1 have historically defined creepage and clearance requirements for IT and telecommunications equipment. These standards provide detailed guidelines on how to determine the appropriate creepage distance based on factors like working voltage, pollution degree, and material group. Always look up the newest requirements, to ensure your safety.

The pollution degree refers to the amount of contamination expected in the operating environment. A higher pollution degree means a more contaminated environment, which in turn requires a larger creepage distance. It's like saying, "If you know your equipment is going to be exposed to a lot of grime, you need to build in extra safety margins."

Ultimately, the goal of these standards is to prevent electrical shock hazards and fire hazards. By adhering to these standards, you can ensure that your 48V system is designed and manufactured in a way that minimizes the risk of electrical breakdown and promotes safe operation. Think of it as electrical common sense!

What Are The Rules For Clearance And Creepage?

Measuring and Verifying Creepage Distances

5. Tools and Techniques for Ensuring Compliance

Okay, so you've designed your system with the appropriate creepage distances on paper. Great! But how do you actually measure those distances in the real world to ensure they meet the requirements? This is where things get a little more hands-on. There are a few methods you can use.

The most common method is using a calibrated measuring tool, such as calipers or a specialized creepage and clearance gauge. These gauges are designed to accurately measure the shortest distance along the surface of the insulation between two conductive parts. You need a steady hand and a good eye for detail. It's like being an electrical surgeon, but instead of operating on people, you're operating on circuits!

Another technique involves using a microscope or other high-magnification device to inspect the creepage path. This is especially useful for identifying potential defects or irregularities that could compromise the insulation. Sometimes, what looks good to the naked eye might reveal hidden flaws under magnification. It's all about those details!

Finally, some manufacturers use automated optical inspection (AOI) systems to verify creepage distances during the manufacturing process. These systems use cameras and image processing algorithms to automatically measure and inspect components, ensuring consistent quality and compliance. These are the superheroes of quality control. If you're using these then chances are you're in pretty good shape.

Creepage And Clearance Lectromec

FAQs about Creepage for 48V Systems

6. Your Burning Questions Answered!

Still got questions? We thought you might! Here are a few frequently asked questions to further clarify the concept of creepage and its relevance to 48V systems:

Q: What happens if the creepage distance is too small?A: If the creepage distance is insufficient, you risk surface tracking, arcing, and ultimately, insulation breakdown, leading to short circuits and potentially fire hazards or electric shock. It's like building a dam with a weak foundation — eventually, it will fail.

Q: Does creepage distance only matter for high-voltage applications?A: While creepage is more critical at higher voltages, it's still important for lower-voltage systems like 48V, especially in environments with high humidity, contamination, or at high altitudes. Every volt counts when it comes to safety!

Q: Where can I find the specific creepage distance requirements for my application?A: Consult the relevant safety standards (e.g., IEC 62368-1, UL 62368-1) for your product type and intended market. These standards will provide detailed guidelines based on factors like working voltage, pollution degree, and material group. Remember to stay updated on the latest revisions of these standards.

Q: Can I just guess at the creepage distance?A: Absolutely not! Creepage distance is a critical safety parameter, and guessing can have serious consequences. Always calculate the creepage distance based on the relevant safety standards and the specific operating conditions of your system. When in doubt, consult with a qualified electrical engineer.